Coil Spring Manufacturing Equipment

Our coil spring manufacturing machines can produce various types of coil springs.

These coil springs are used for automobiles, trains and heavy machines.

We have made the machines for wire diameter up to 100mm.

STEP 5LOAD TESTING

Load Testing Machine

This machine can measure the load of coil springs with its specified height. Then the coil springs will be classified by the results of its load.

Load Testing UnitB663T

Overview

This is an equipment to measure a load of coil spring after painting one by one and to classify the measured results to 5 ranks. Classification is done by load measuring under specified height. No good product is classified to + NG and - NG, and ejected outside machine. Good product is classified to (+, 0, -) and ejected outside machine. Jigs, which are changed in accordance with both ends shape of coil spring, can be automatically changed by jig changer (Option).

Constitution

- Testing Machine

- Jig Changer (Option)

- Marking Device

- Classification C/V

- Positioning Device and Transfer Device

Specification

*Table can be scrolled horizontally

| Specification of Product | Bar Dia. | 8~20mm |

|---|---|---|

| Outer Dia. of Coil | 85~200mm | |

| Inner Dia. of Coil (Cylindrical) | 50~160mm | |

| Inner Dia. of Coil (Conical) | Min. 50mm | |

| Free Length (Before Presetting) | 200~600mm | |

| Free Length (After Presetting) | 160~550mm | |

| Direction of Coil | Right | |

| Specification of Machine | Number of Head | 1 head (System to treat one spring every one cycle) |

| Pressing Capacity | Max. 2000kgf | |

| Load Detection | Load Cell | |

| Pressing Drive | AC Servo Motor | |

| Temperature of Coil Spring | Normal Room Temperature | |

| Measuring Method | Load Measuring under specified height | |

| Classification | 5 ranks (+NG, +, 0, -, -NG) | |

| Cycle Time | 10 sec/cycle (about 600 pcs./Hr) | |

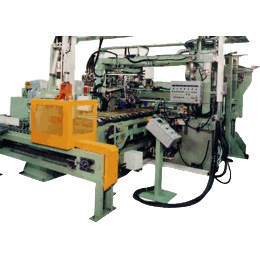

Presetting & Load Testing MachineSA42M

Overview

This machine has a function to make a setting and testing of coil spring continuously. Testing results are classified to 5 ranks (+NG,+,0,-,-NG) and indicated at a display. The machine has a construction to increase or decrease a pressure against spring by power source of AC servo motor and through a ball screw. Consequently, high speed and smooth movement and measuring can be done.

Constitution

- Setting and Testing Machine

- Spring Receiving Device Safety

- Cover with automatic opening and closing

Specification

*Table can be scrolled horizontally

| Specification of Product | Outer Dia. of Coil | 70~200mm |

|---|---|---|

| Free Height | 150~550mm | |

| Solid Height | Min. 45mm | |

| Specification of Machine | Presetting Capacity | 4000kgf |

| Testing Capacity | 2000kgf | |

| Load Detector | Load Cell | |

| Re-Setting Function | Enable |

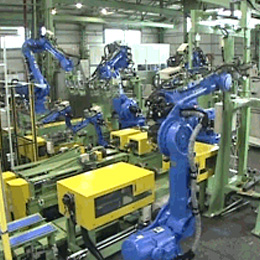

Load Classification UnitB553-T2

Overview

This is an equipment to measure a load of coil spring after painting one by one and to classify the measured results to 5 ranks. Classification is done by load measuring under specified height. No good product is classified to + NG and - NG, and ejected outside machine. Good product is classified to (+, 0, -) and ejected outside machine. Jigs, which are changed in accordance with both ends shape of coil spring, can be automatically changed by jig changer (Option).

Constitution

- De-hooking Device

- Orientation

- NG Chute

- Loader to Testing Machine

- Testing Machine

- Unloader from Testing Machine

- Marking Device

- Unloader after Marking

- Classification Conveyer

- Dryer for Marking

- Inspection Device for Marking

Specification

*Table can be scrolled horizontally

| Specification of Product | Bar Dia. | 10~20mm |

|---|---|---|

| Outer Dia. of Coil | 85~190mm | |

| Inner Dia. of Coil | 60~165mm | |

| Free Length | 200~550mm | |

| Weight of Coil | 1.0~8.0kg/pc | |

| Solid Height | over 60mm | |

| Total Turn | Max. 16 | |

| Pitch of Coil | Max. 180mm | |

| Direction of Coil | Right/Left | |

| Cycle Time | 4.5 sec/pcs. (average) | |